Predictive IIoT Platform in Smart Industrial Maintenance

STOP REACTING. START PREDICTING. In the hyper-competitive world of industrial automation, the biggest threat to your bottom line isn’t new competition—it’s the costly, unpredictable failure of your own equipment. Are you still accepting hundred thousand per hour price tag of unplanned downtime?

We partnered with an automation leader to shift this paradigm. This is the blueprint for how strategic software outsourcing delivered a powerful Industrial IoT (IIoT) platform, leveraging deep data analytics and cutting-edge IoT device management to achieve a demonstrable 50% reduction in equipment downtime.

1. The Client’s Vision: Escaping the Maintenance Trap

Our client, a true innovator with over 15 years of mastery in the automation industry, understood the severe pain felt by plant managers: systems were disconnected, data was scattered, and maintenance was a frantic race to fix what was already broken.

Their bold, audacious goal was to build a single, unified system—a “Predictive Platform”—that could serve as the control center for industrial assets in critical sectors like water management, smart buildings, and energy grids. They needed a solution that would solve future global challenges by providing not just data, but foresight.

But how do you transform thousands of existing physical machines into one intelligent, predictive system?

This vision required a rare blend of expertise: low-latency IoT hardware integration, massive-scale data analytics processing, and flawless multi-platform delivery. Facing the complexity and speed required, the client chose the strategic path of software outsourcing to rapidly deploy a world-class, specialized team—our team.

2. The Project: Building the “Brain” of the Industrial Plant

The heart of our solution wasn’t just a dashboard; it was a complex, intelligent core engineered for speed and precision.

The Power of Precision Data Analytics: Forecasting Failure

Ask yourself: What is the true value of your data? If it doesn’t prevent future losses, it’s just history.

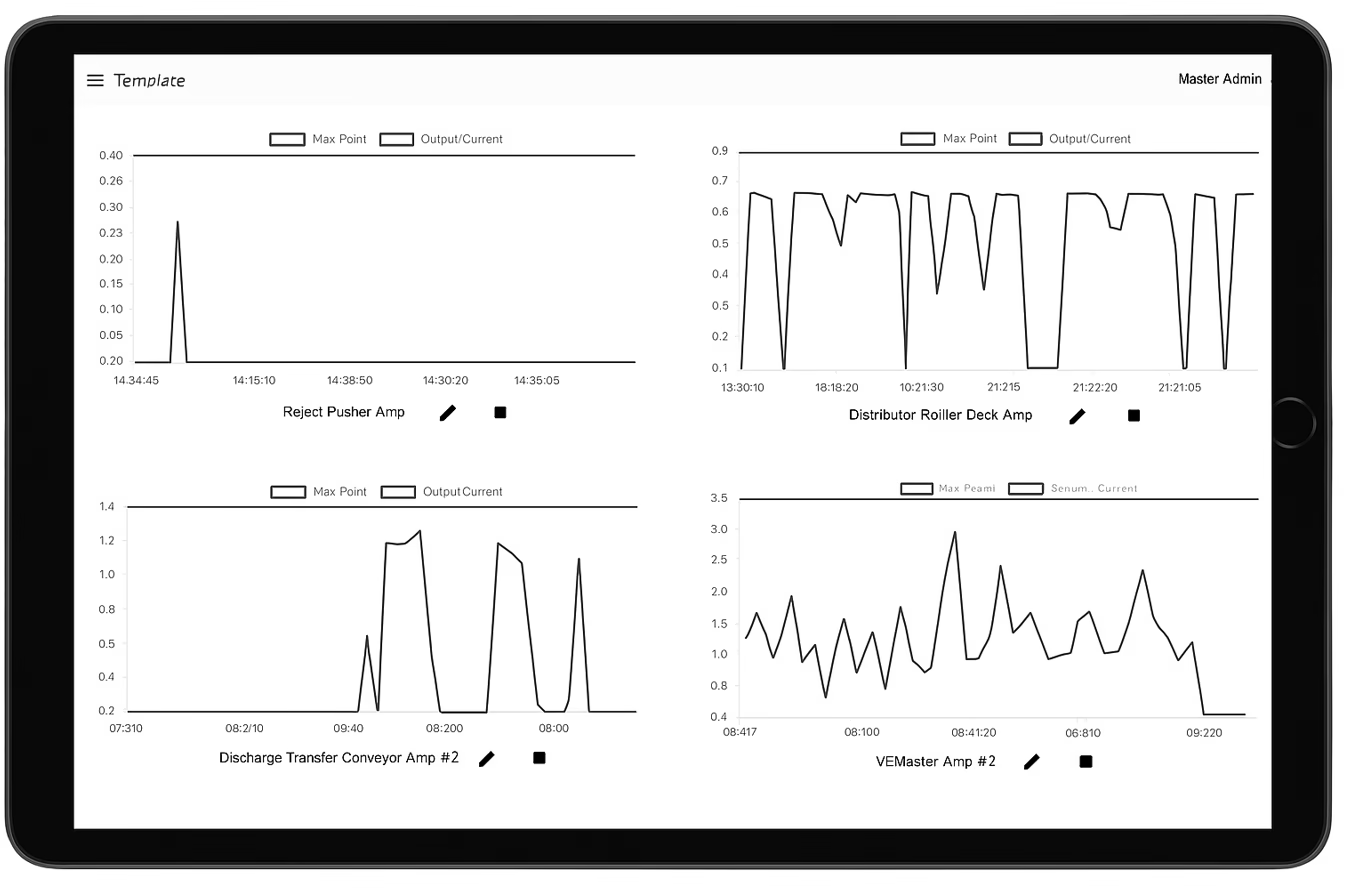

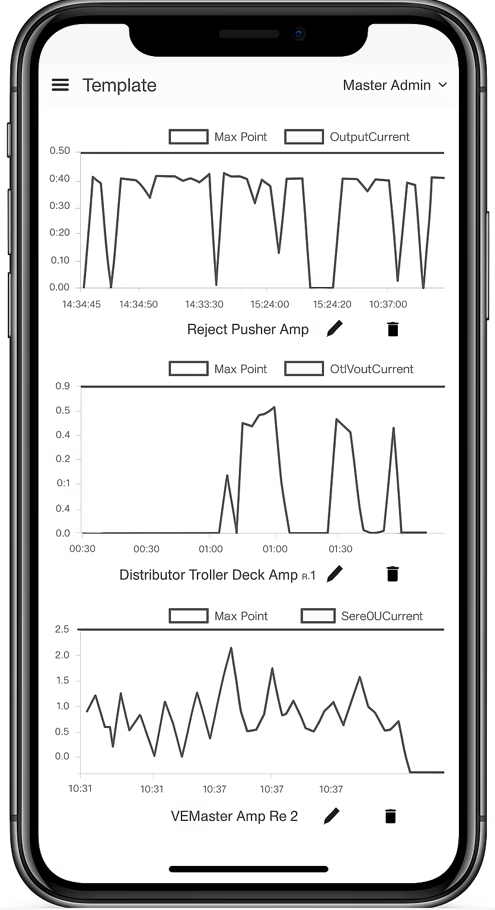

Our application is centered on transforming raw signals into actionable, visualized intelligence. We use dynamic charts and graphical simulations to immerse users in a crystal-clear narrative of machine health.

- From Data Point to Prediction: The platform doesn’t just display temperature; it analyzes the rate of temperature change across 10,000 data points to predict a bearing failure two weeks in advance.

- Continuous Improvement Loop: The data analytics engine constantly evaluates machine performance against industrial protocols, enabling continuous, data-driven system optimization.

This deep commitment to data analytics is what converts capital expenditure into a competitive asset.

Mastering IoT Device Management and Control

The platform gives users unparalleled control, moving from passive monitoring to proactive command:

- Remote Control & Performance Tracking: Users can directly control devices (e.g., adjust frequency drives like the Power Flex 525) and track real-time performance metrics remotely, instantly eliminating unnecessary site visits.

- Predictive Maintenance Scheduling: By identifying the exact point of required intervention, the system enables managers to align maintenance with planned downtime, minimizing unplanned downtime and maximizing the useful life of the asset.

- The Instant Lifeline: Automated Alerting & Intervention: When an anomaly is detected (e.g., an unusual vibration detected by a BLE Tag or a power spike), the system instantly issues a high-priority alert. Critically, the customer retains full, ultimate permission to remotely terminate the device for safety or restore it after a software patch. This level of immediate, secure control is the definition of gold-standard IoT device management.

- Universal Accessibility: We architected the system for ubiquitous access, ensuring technicians on the floor and executives in the office can interact with the same critical data seamlessly across web, tablet, and mobile.

3. The Blueprint: Technology, Team, and Transparency

When facing a project of this complexity—blending low-level sensor application logic with high-level data analytics visualization—we knew our approach had to be as innovative as the product itself.

A. Sensor Application Development and Hardware Integration

We initiated the project with deep sensor application development:

- Device Implementation: Our team seamlessly integrated diverse industrial components (Raspberry Pi, Power Flex 525, BLE Tags) to create a robust and secure data collection backbone.

- The Data Funnel: The solution rigorously follows the three essential steps: Collect, Preprocess (cleaning and normalizing raw industrial inputs), and Evaluate (feeding the cleansed data into the predictive models).

B. The High-Performance IoT Web Application

The user experience had to be flawless to drive adoption.

- Design Philosophy: Consistency is King: The first phase focused on meticulous UI/UX development. All user roles—from the all-powerful Super Admin to the standard User—follow a Unified UX. This consistency drastically cuts down on training time, eliminates user error, and guarantees rapid adoption.

- Technology Stack: We strategically chose Hybrid technology with the Ionic framework. This singular codebase allowed us to deliver the IoT web application to multiple platforms (web, iOS, Android) simultaneously, maximizing speed-to-market and ensuring long-term maintenance efficiency.

C. The Engine of Partnership: Process Excellence

In this 24+ month software outsourcing engagement, transparency was paramount. Our dedicated team (1 Lead, 4 Software Engineers, 1 Data Analyst, 1 QC Engineer) used industry-best tools (Jira, Trello, Microsoft 365) and rigorous Agile practices. This proactive, structured communication ensured the client was always connected to our internal team, making the work feel like an extension of their own highly efficient operation.

4. The Return on Foresight: Quantified Results

This project didn’t just meet specifications; it delivered profound, measurable operational savings. The transition from a reactive model to a predictive one yielded dramatic ROI:

Metric | Before Our Solution | After Our Solution | Business Impact & ROI |

Unplanned Downtime | Unpredictable and catastrophic (Average cost around $120,000/hour) | Reduced Unplanned Downtime by 70-75% | MAXIMIZED UPTIME: Hours gained are direct revenue. This avoids emergency shutdowns that cripple production. |

Maintenance Costs | Reactive, emergency repairs, and excessive inventory | Maintenance Costs Reduced by 15-30% | SAVINGS: Eliminates expensive emergency call-out fees, over-servicing of healthy assets, and excessive spare parts inventory. |

Decision Speed | Slow, manual data correlation, high latency (> 1 hour) | Real-Time Insight with alerts delivered in under 500 milliseconds | AGILITY: Provides days or weeks of lead time, allowing managers to schedule maintenance during off-peak hours. |

Operational Efficiency | Limited by operational risk and machine wear-and-tear | Overall Equipment Effectiveness (OEE) Boosted by 10-20% | GROWTH: Ensures assets are constantly running at peak performance, driving maximum output and productivity. |

The Final Verdict: Competitive Advantage Secured

By leveraging strategic software outsourcing, our client secured a market-leading IoT solution that provides unparalleled control, superior data analytics, and robust, future-proof IoT device management. They didn’t just solve their customers’ maintenance problems; they equipped them with the ultimate competitive advantage: the power to predict the future of their assets.

Connecting NNG

We'd be happy to speak with you. Please don’t hesitate to contact us using the information below.