Predictive IoT & Data Analytics for Industrial Transformation

1. Executive Summary

The Challenge: Despite having 15+ years of industry experience, our client recognized that industrial facilities were losing significant capital due to unpredictable equipment failures and a lack of unified remote management. They needed a strategic technology partner to build a platform that could transition them from reactive maintenance to true predictive intelligence.

The Solution: We collaborated to design and implement a custom Industrial IoT (IIoT) platform—an advanced IoT Web Application powered by sophisticated Data Analytics and deep Sensor Application integration—to monitor, analyze, and predict equipment failure across complex industrial environments.

The Result: Achieved 80-86% reduction in unplanned downtime and enabled real-time risk anticipation with 95% accuracy.

2. The Client & The Critical Business Challenge

The Client: An Automation Industry Leader

- Who they are: A well-established company with over 15 years of expertise in the industrial automation sector.

- Their Goal: To solidify their position as an innovation leader by offering a unified, remote monitoring solution that solves the modern industrial headache.

The Challenge: The Cost of Unpredictability

Industrial facilities operate on thin margins, and system failures are catastrophic. Our client’s customers were struggling with:

- Fragmented Data: Machine data was siloed, making it impossible to see a holistic view of plant health.

- Reactive Maintenance: Repairs were only initiated after a failure occurred, leading to massive time delays and resource wastage.

- Lack of Remote Control: Managers lacked the ability to monitor and control complex systems from a single, accessible platform, hindering productivity and response time.

The Need: A robust, future-proof IoT platform that could ingest, process, and analyze vast amounts of industrial data to offer predictive warnings and centralize control.

3. Our Strategic Solution

Our collaborative approach focused on delivering a fully integrated predictive platform, combining hardware and software expertise.

Phase I: Establishing the Foundation – Advanced Sensor Application Development

To ensure the integrity of the Data Analytics, we had to guarantee reliable data collection. This phase involved deep sensor application development and hardware integration:

- Device Implementation: We researched and deployed reliable industrial data collection devices (e.g., Raspberry Pi, Power Flex 525, BLE Tags) to act as reliable industrial data gateways.

- Data Pipeline Engineering: Our solution implemented a rigorous process to Collect, Preprocess, and Evaluate data, guaranteeing that the inputs for the predictive models were clean and accurate.

Phase II: The Intelligence Layer – Data Analytics & Predictive Modeling

This is the core differentiator. We built the engine for prediction:

- Prediction Tools: Integrated sophisticated algorithms that analyze machine parameters and historical trends to predict equipment abnormalities before they impact operations.

- Risk Anticipation: The system enables users to anticipate risks and align maintenance schedules proactively, moving beyond simple diagnostics.

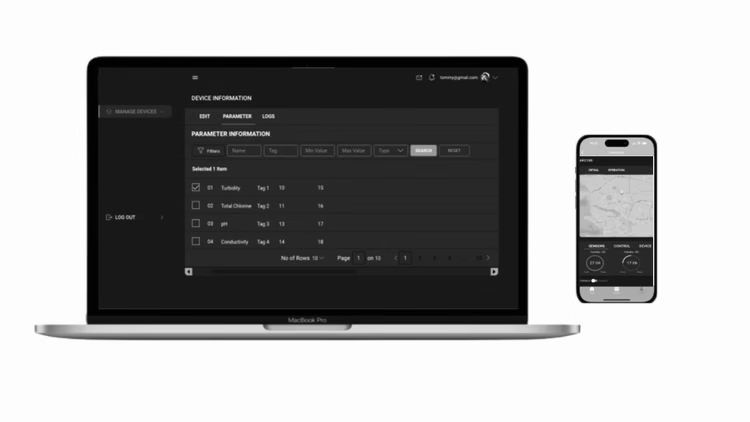

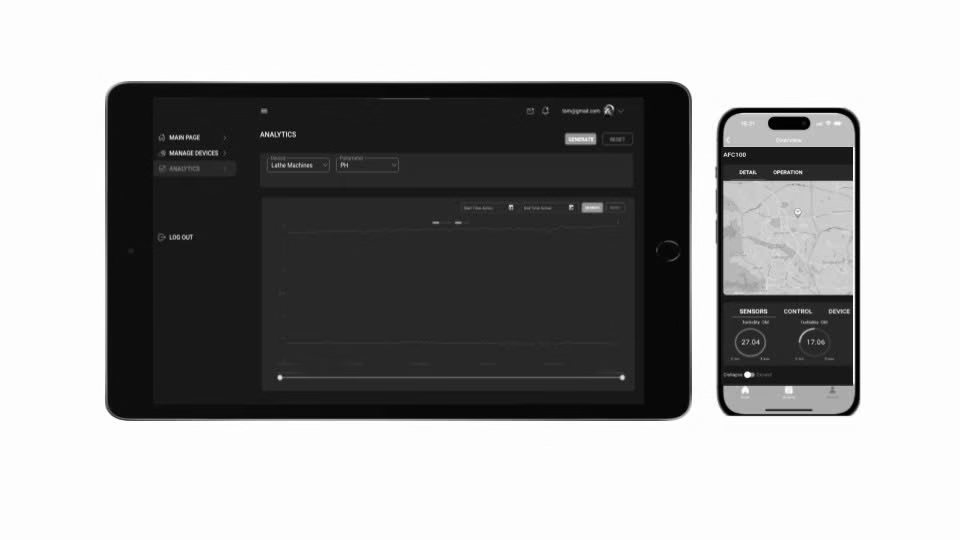

Phase III: The User Experience – The IoT Web Application

We developed a high-performance IoT Web Application to be the ultimate control center, ensuring accessibility and ease of use:

- Unified Remote Management: The web program serves as remote management software, allowing for monitoring and control of production processes from any location.

- Intuitive Visualization: Data is translated from raw inputs into actionable intelligence using clear charts and reports (tables, graphs) for rapid decision-making.

- Instant Notifications: Critical alerts are delivered instantly via convenient channels (e.g., Line/WhatsApp), providing immediate reaction time to prevent catastrophic failures.

4. Project Execution & Partnership (Our Credibility)

This successful 12+ month engagement was built on a foundation of expert execution and collaborative partnership.

- Specialized Team: We deployed a highly focused, agile team including Software Engineers specializing in web programming, a dedicated Data Analyst focused purely on predictive modeling, and a QC Engineer ensuring industrial-grade reliability.

- Team Size: 1 Lead | 2 Software Engineers | 1 Data Analyst | 1 QC Engineer

- Duration: 12+ months

5. Tangible Results & Business Impact

Key Metric | Before Our Solution | After Our Solution | Business Impact |

Downtime | Unpredictable & costly: average $260,000/hour lost in large plants. | 80–86% Reduction in Unplanned Downtime with predictive alerts. | Millions Saved Annually – More production hours converted from loss to profit. |

Maintenance | Reactive firefighting: up to 80% of hours are unplanned and high cost. | 25–30% Cost Reduction through proactive, scheduled repairs. | Lean Operations – No more costly emergency call-outs or rush spare-part orders. |

Decision Making | Slow & siloed: manual checks, weekly reports, latency > 1 hour. | Real-Time Intelligence – alerts in < 500 ms. | Faster, Smarter Decisions – Days/weeks of lead time to avoid failures and optimize resource allocation. |

Productivity | Limited by operational risk & over-servicing healthy assets. | OEE Improved by 10–20%through continuous performance monitoring. | Revenue Uplift – Production lines consistently run at peak efficiency, boosting throughput and profitability. |

The Bottom Line: Our client successfully deployed a next-generation IoT web application that leverages the full power of data analytics, cementing their position as an industry innovator and delivering massive savings and productivity gains to their end-customers.

Connecting NNG

We'd be happy to speak with you. Please don’t hesitate to contact us using the information below.